Usage of Scanning Electronic Microscope for Helicopter applications.

Gaël MONAVON

Airbus Helicopters, Aéroport International Marseille-Provence, 13725, Marignane Cédex

Scanning Electronic Microscopes (SEM) are key means for Airbus Helicopters Material & Processes laboratories. They are used at different value chain steps of the helicopter (development, certification, manufacturing, in-service). The objective of this conference is to provide an overview of their usage.

gael.monavon@airbus.com

KEY WORDS: Scanning Electronic Microscope, Material & Processes characterization, Reach, Fractography, EDX

After a reminder of the role of Material & Processes laboratory for an helicopter manufacturer, the importance of Scanning Electronic Microscopes and their interaction with other laboratory means will be discussed.

Different usages of SEM will be highlighted:

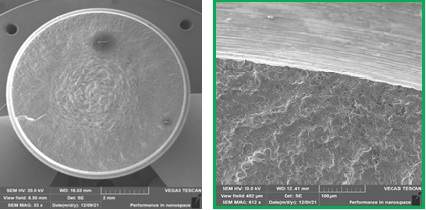

- Fractography analysis of coupons tests: Some examples of failure analysis both on metallic materials (rotative bending fatigue specimen) and composite materials (tensile and bending static specimen) will be presented. In particular, it will be reminded that SEM is a key equipment to ensure the validity of a mechanical test result.

- Development of new surface treatments in the frame of Reach regulation: Presentation will focus on challenges for laboratory in term of observations by SEM (low acceleration voltage, high resolution…)

- Part certification: The usage of striation counting by SEM in this frame will be explained. In particular, the way to proceed to perform this measurement and the result provided to Stress Department will be described.

- Particle analysis performed with EDX (Energy Dispersive X-ray spectroscopy) coupled with a SEM: the presentation will explain how the chemical analysis of a metallic particle is done by EDX but will also insist on the necessity to link it with an analysis of the morphology

Finally, perspectives and industrial expectations (like more automation, usage of artificial intelligence) will be discussed.

Figure: Fracture Surface of a Fatigue specimen by SEM